Klasipikasyon sa AWS: AWS 5.9

DESKRIPSYON:

Ang stainless steel welding wire adunay taas nga efficiency sa cladding, maayo nga teknikal nga performance sa welding sa all-position welding. Kini kaylap nga gigamit sa industriya: istruktura sa bilding, sakyanan, inhenyeriya sa taytayan, makinarya sa pagmina, riles, tubo sa lana, kagamitan sa gas pressure-bearing, power equiment, ug uban pa.

NUMERO SA MODELO UG GIDAK-ON:

1. Serbisyo sa OEM nga gikan sa pabrika.

2. Modelo: ER308 ER308L ER308LSi ER309 ER309L ER316 ER316L ER316LSi ug uban pa.

3. Gidak-on sa alambre sa MIG: 0.8mm 0.9mm 1.0mm 1.2mm 1.6mm.

4. Gidak-on sa alambre nga TIG: 1.6mm 2.0mm 2.4mm 3.2mm 4.0mm.

PASIUNA:

Nagatanyag kami og lain-laing klase sa stainless steel welding wire, lakip na ang Mig solid welding wire, Tig rod welding wire ug submerged-arc welding wire, tanan taas og kalidad ug gibaligya sa tibuok kalibutan.

Gawas sa 308 ug 309, nagtanyag usab kami og 304, 321, 347, 316L, 310, 2209, ug 201. Ingon man usab sa mga espesyal nga espesipikasyon sama sa 318L, 904L, 2594, NiCrMo-3, Ni1.

PAG-EMPLETO:

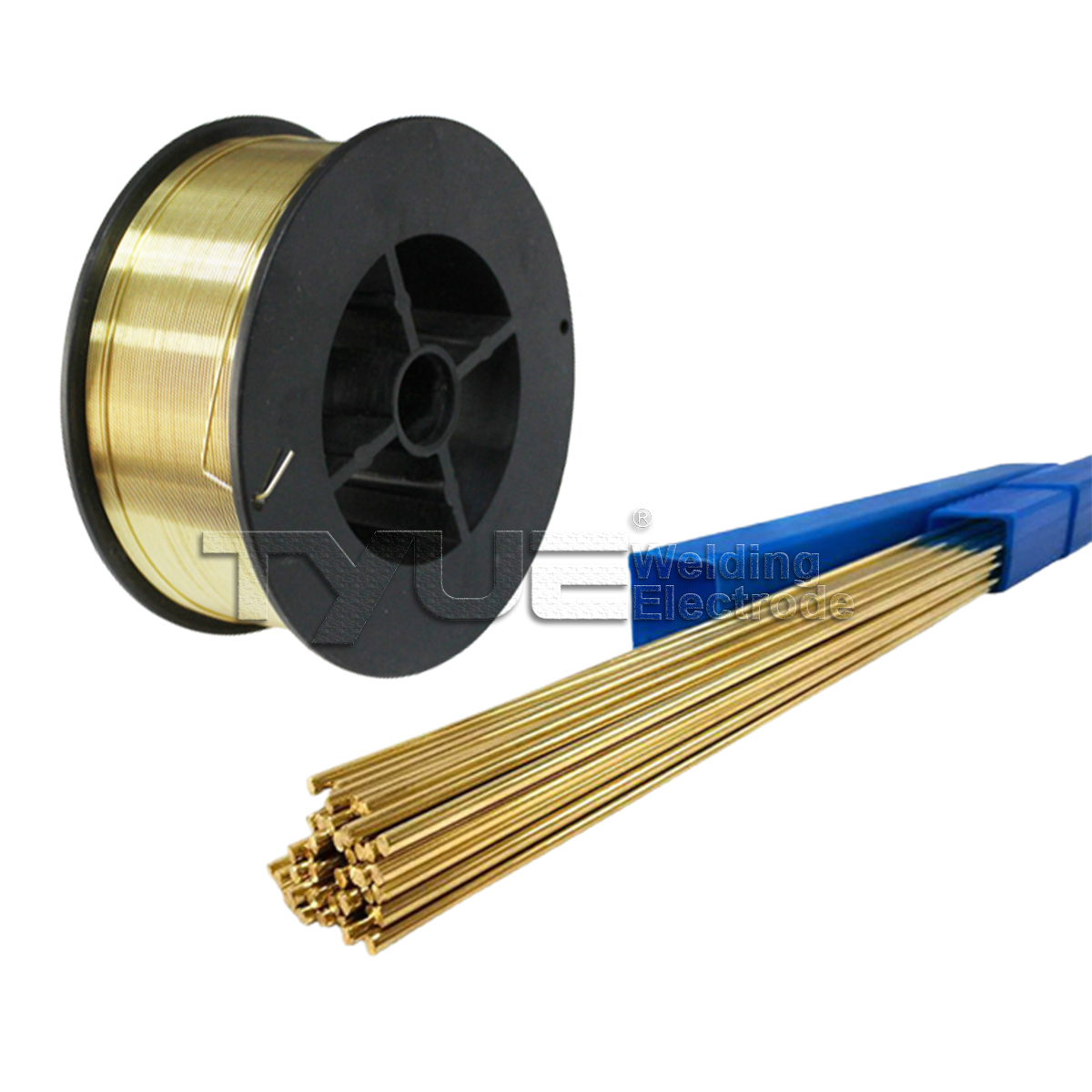

Pagputos sa wire sa welding sa MIG (pack sa spool ug drum)

Diametro: 0.8 - 2.0mm

Pakete: 1 kg/spool, 5 kg/spool, 15 kg/spool, 20 kg/spool, 100 kg/drum, 200 kg/drum

Pagputos sa alambre sa welding nga Tig rod (plastik nga tubo)

Diametro: 1.0 - 5.0mm

Pakete: 5 kg/pakete

Nalubog nga alambre sa arc welding

Diametro: 2.5 - 5.0mm

Pakete: 20kg/pakete, 25 kg/pakete

Gidawat ang neyutral nga packaging ug OEM!

MGA KEMIKAL NGA KOMPOSISYON SA STAINLESS STEEL WELDING WIRE:

| Numero sa Modelo | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| 304 | 0.08 | 0.30-1.00 | 2.00 | 0.045 | 0.030 | 18.00-20.00 | 8.00-11.00 | 0.18 | 0.003 |

| 304L | 0.03 | 0.30-1.00 | 2.00 | 0.045 | 0.030 | 18.00-20.00 | 8.00-12.00 |

|

|

| ER307 | 0.04-0.14 | 0.30-0.65 | 4.30-4.75 | 0.030 | 0.030 | 19.50-22.00 | 8.00-10.70 | 0.5-1.5 | 0.75 |

| ER308 | 0.08 | 0.30-0.65 | 4.30-4.75 | 0.030 | 0.030 | 19.50-22.00 | 9.00-11.00 | 0.75 | 0.75 |

| ER308L | 0.03 | 0.30-0.65 | 1.50-2.30 | 0.03 | 0.02 | 19.5-21.5 | 9.00-11.00 | 0.75 | 0.75 |

| ER308LSi | 0.03 | 0.65-1.00 | 1.60-2.40 | 0.03 | 0.02 | 19.5-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER309 | 0.12 | 0.30-0.65 | 1.00-2.50 | 0.03 | 0.03 | 24.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER316 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 18.00-12.00 | 11.0-14.0 | 2.0-3.0 | 0.75 |

| ER316L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER316LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER310 | 0.08-0.15 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.75 |

| ER347 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 19.0-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER317 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.01 | 18.5-20.5 | 13.0-15.0 | 3.0-4.0 | 0.75 |

| ER321 | 0.08 | 0.3-0.65 | 1.5-2.5 | 0.03 | 0.01 | 18.5-20.5 | 9.0-10.5 | 0.75 | 0.75 |

| Numero sa Modelo | Kusog sa pagkunot Rm(Mpa) | Kusog sa ani Rel o Rp0.2 (Mpa) | Pag-inat (%) | Numero sa Modelo | Kusog sa pagkunot Rm(Mpa) | Kusog sa ani Rel o Rp0.2 (Mpa) | Pag-inat (%) |

| 304 | 550 | -- | 25 | ER309LSi | 510 | 320 | 25 |

| 304L | 510 | -- | 25 | ER316 | 510 | 320 | 25 |

| ER307 | 590 | 350 | 25 | ER316L | 510 | 320 | 25 |

| ER308 | 550 | 350 | 25 | ER316LSi | 510 | 320 | 20 |

| ER308L | 510 | 320 | 25 | ER310 | 550 | 350 | 25 |

| ER308LSi | 510 | 320 | 25 | ER347 | 550 | 350 | 25 |

| ER309 | 550 | 350 | 25 | ER317 | 550 | 350 | 25 |

| ER309L | 510 | 320 | 25 | ER321 | 550 | 350 | 25 |

| Komposisyon sa TIG ug MIG stainless steel welding wire | ||||||||||

| YB5092-2005 | AWS | Komposisyon sa Kemikal % | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo |

| ||

| H08Cr20Ni9Mn7Si | ER307Si | 0.075 | 0.78 | 6.7 | 0.022 | 0.01 | 19.8 | 8.8 |

|

|

| H06Cr21Ni10 | ER308 | 0.045 | 0.45 | 1.9 | 0.02 | 0.009 | 20.8 | 9.8 |

|

|

| H0OCr21Ni10 | ER308L | 0.02 | 0.32 | 1.9 | 0.011 | 0.006 | 20 | 10.2 |

|

|

| H06Cr21Ni10Si | ER308Si | 0.045 | 0.85 | 1.5 | 0.022 | 0.01 | 20.8 | 9.8 |

|

|

| H06Cr24Ni13 | ER309 | 0.06 | 0.45 | 1.9 | 0.019 | 0.009 | 24.3 | 13.2 |

|

|

| H06Cr24Ni13Si | ER309Si | 0.06 | 0.79 | 1.95 | 0.019 | 0.009 | 24.7 | 13.2 |

|

|

| H03Cr24Ni13 | ER309L | 0.02 | 0.42 | 1.8 | 0.02 | 0.01 | 24.8 | 13.2 |

|

|

| H03Cr24Ni13Si | ER309LSi | 0.018 | 0.8 | 1.7 | 0.02 | 0.01 | 23.5 | 13.5 |

|

|

| H21Cr16Ni35 | ER330 | 0.2 | 0.38 | 1.5 | 0.022 | 0.01 | 16.5 | 34.5 |

|

|

| H06Cr19Ni12Mo2 | ER316 | 0.04 | 0.4 | 1.9 | 0.02 | 0.01 | 19.5 | 11.8 | 2.3 |

|

| H06Cr19Ni12Mo2Si | ER316Si | 0.05 | 0.7 | 1.92 | 0.02 | 0.01 | 19.5 | 11.8 | 2.3 |

|

| H03Cr19Ni12Mo2 | ER316L | 0.019 | 0.38 | 1.8 | 0.018 | 0.01 | 19.8 | 12.2 | 2.5 |

|

| H03Cr19Ni12Mo2Si | ER316LSi | 0.06 | 0.85 | 1.7 | 0.022 | 0.01 | 18.8 | 12.6 | 2.4 |

|

| H03Cr17Ni14Mo3 | ER317L | 0.02 | 0.38 | 1.8 | 0.02 | 0.01 | 18.8 | 13.8 | 3.6 |

|

| H08Cr19Ni12Mo2Nb | ER318 | 0.06 | 0.42 | 1.5 | 0.022 | 0.01 | 18.5 | 11.8 | 2.3 |

|

| H07Cr20Ni34Mo2Cu3Nb | ER320 | 0.06 | 0.4 | 1 | 0.022 | 0.01 | 19.8 | 33.3 | 2.8 | Nb0.7 |

| H02Cr20Ni34Mo2Cu3Nb | ER320L | 0.018 | 0.33 | 1.5 | 0.013 | 0.01 | 19.8 | 33.6 | 2.5 | Nb0.35 |

| H08Cr20Ni10Ti | ER321 | 0.06 | 0.45 | 1.5 | 0.022 | 0.01 | 20.8 | 9.8 |

| Ti9xC-1.0 |

| H08Cr21 Ni10Nb | ER347 | 0.055 | 0.48 | 1.8 | 0.021 | 0.008 | 20.8 | 9.8 |

| Nb1xC-1.0 |

| H12Cr26Ni21 | ER310 | 0.09 | 0.5 | 1.66 | 0.02 | 0.01 | 25.5 | 20.5 |

|

|

| H02Cr20Ni25Mo4Cu | ER385 | 0.02 | 0.3 | 1.5 | 0.018 | 0.01 | 20.2 | 24.8 | 4.8 | Cu 1.80 |

| H03Cr22Ni9Mo3N | ER2209 | 0.022 | 0.5 | 0.9 | 0.02 | 0.01 | 22.5 | 8.8 | 3.3 | N0.08-0.20 |

| H04Cr25Ni5Mo3Cu2N | ER2553 | 0.027 | 0.5 | 1 | 0.025 | 0.015 | 24.8 | 5.5 | 3.2 | N0.1-0.25 |

| H1 5Cr29Ni9 | ER312 | 0.09 | 0.38 | 1.5 | 0.022 | 0.01 | 29.5 | 8.5 |

|

|

| H03Cr24Ni13MoL | ER309L Mo | 0.023 | 0.45 | 1.5 | 0.022 | 0.01 | 23.8 | 13.2 | 2.2 |

|

| H05Cr17Ni4Cu4Nb | ER630 | 0.04 | 0.39 | 0.5 | 0.022 | 0.01 | 16.5 | 4.8 |

| Cu;3 Nb;0.28 |

| H08Cr26Ni5Mo2 | ER453s | 0.06 | 0.3 | 0.4 | 0.022 | 0.01 | 25.8 | 4.8 | 2.1 |

|

| H08Cr21Ni10Mn6 |

| 0.06 | 0.35 | 5.5 | 0.022 | 0.01 | 20.8 | 9.8 |

|

|

| H05Cr22Ni11Mn6Mo3VN | ER209 | 0.04 | 0.4 | 4.5 | 0.022 | 0.01 | 21.5 | 10.8 | 2.2 | N;0.20 V;0.18 |